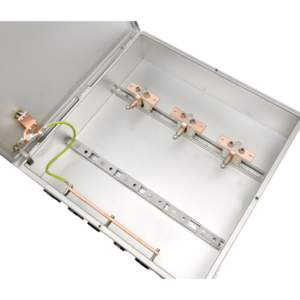

Purge Panel

This method of explosion protection involves a meticulous approach to maintaining the enclosure’s internal pressure at a level that effectively bars the ingress of flammable gases, vapors, dust, or fibers, thus preventing any potential ignition. Simultaneously, a continuous airflow (or inert gas) is regulated to dilute and eliminate any potentially explosive atmosphere.

This form of protection is applied to equipment that generates sparks, electric arcs, or hot surfaces during normal operation. It is particularly suited for safeguarding intricate industrial machinery, including control systems, designed to function within potentially explosive atmospheres. This encompasses a wide range of equipment, such as large machines, slip ring or collector motors, switch cabinets, control cabinets, and analytical instruments.

Open 24/7 support for help

Contact us to know more.

Product Certifications

- ATEX

- IECEX

Area Clasification

- Gas: Zone 1 & 2

- Dust: Zone 21 & 22

Type of Protection

- :-pxb

“”pxb”” is pressurized encapsulated equipment with a device protection level of “”Gb”” or “”Db””. It protects normal industrial components which can be operated in zone 1/21 due to the pressurized enclosure. - :-pyb

“”pyb”” is pressurized encapsulated equipment with the device protection level “”Gb”” or “”Db””. It protects components which correspond to the device protection level “”Gc”” or “”Dc””. The protection level “”pyb”” therefore permits the operation of approved components of zone 2/22 in zone 1/21 - :-pzc

“”pzc”” is pressurized encapsulated equipment with the device protection level “”Gc”” or “”Dc””. It protects normal industrial components that can be operated in Zone 2/22 due to the pressurized enclosure”

Standards / Norms

- IEC / EN 60079-0

- IEC / EN 60079-2

- IEC / EN 60079-14