Fire Rated Enclosure

Electrical cabinets are meticulously engineered to perform exceptionally well in the most extreme temperature conditions. Whether exposed to scorching highs of up to +250ºC or frigid lows as cold as -60ºC, these cabinets are up to the task. They’re purpose-built to thrive in environments characterized by high humidity or, conversely, extremely low humidity levels, which guarantees the durability and sustained performance of the sensitive electrical components housed within. These cabinets are your reliable solution for protecting critical electrical equipment in the harshest of environmental conditions.

Open 24/7 support for help

Contact us to know more.

Electrical enclosure for Extreme Temperature:

Electrical cabinets for areas with extreme temperature conditions, both in high temperature +250ºC and in low temperature

-60ºC; cabinets are prepared for a high humidity concentration or a very dry environment, with the guarantee that the electrical components will continue operating after many years. They are designed with the tightness required for electrical cabinets (IP66, IP67,and IP68) depending on their location and with the maximum durability to the corrosion, it is possible to use stainless steel AISI 304l or AISI 316L (marine). Different sizes and customized designs for a junction boxes with screw openings or with revolving door available.

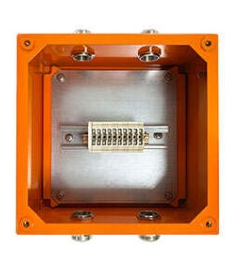

PH120 FIRE & FLAME RATED ENCLOSURE

OEM enclosures have been successfully tested to in fire standards. PH120, according UNE EN 50200.

Fire resistant enclosures and junction boxes are used to maintain electrical and electronic circuit integrity to emergency lighting, power and control cables.

Delvalle designs and manufacture:

• Fire and flame rated enclosures

• Fire rated junction boxes

• Fire rated cabinets depending on their location and for areas with the possibility of high temperature, they are designed with the tightness required for Fire Rated Enclosures (IP66) depending on their location and with the maximum durability to the

corrosion, it is possible use AISI 304L / AISI 316L (high corrosion protection).