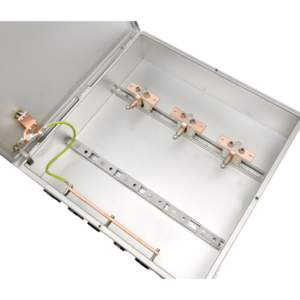

Ex e Junction Box

“Increased Safety Ex e” represents an explosion protection approach implemented in installations to enhance security against the risks associated with elevated temperatures, arcs, and sparks originating from electrical equipment in hazardous areas. This method specifically prohibits the use of equipment that typically generates sparks. The primary goal of the Increased Safety standard (Ex e) is to provide a robust and impact-resistant enclosure for electrical equipment. Furthermore, it ensures that the equipment’s internal components do not produce any sparks, arcs, excessive temperatures, or current creepage that could potentially ignite the flammable atmosphere in the surrounding hazardous area, zone, or workspace.

Category:

Junction Box

Open 24/7 support for help

Contact us to know more.

Applicable Industry / Area

- Oil refineries

- Onshore

- Offshore

- Pharmaceuticals

- Painting

- Chemical & Petrochemical

- Water Treatment

- Heat tracing

- HVAC

- Aeronautical

- Fuel Dispensing stations

- Marine

- Paper

- Textile

- Fragrance

Application Examples

- Instrumentation JB

- Loop in Loop out JB

- Lighting JB

- Motor Connection JB

- Interconnection JB

- Terminal JB

Standards / Norms

- IEC / EN 60079-0

- IEC / EN 60079-1

- IEC / EN 60079-31

Body / Cover

- Marine grade Copper Free Aluminum Light Alloy

Hazardous area of Installation

- Zone 1 / Zone 2 (Gas)

- Zone 21 / Zone 22 (Dust)

- Temperature Rating: T3….T6

- Gas Group: IIB+H2

- Protection Degree: IP66, Conforming IEC 60529

- Ambient Temperature: -60°C ÷ +80°C

Certificates

- ATEX(Europe)

- IECEx(Global)

- ECASEx(UAE)

- NEC 505(North America)

- NEC 500(North America)

- TR CU(EAC)

- INMETRO(BRAZIL)

- RINA(MARINE)

- PESO(INDIA)

- KC(KOREAN)